Atom Probe Tomography Sample Preparation

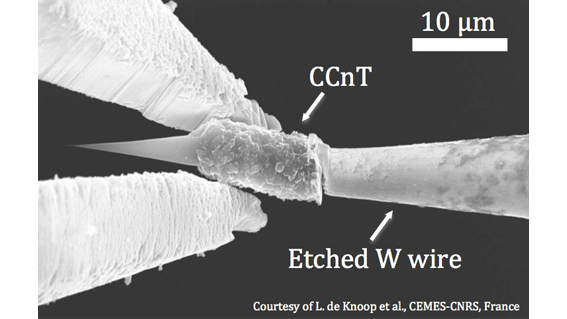

The sharp tip shape required for Atom Probe Tomography (APT) samples are usually fabricated using an annular milling pattern with a focussed ion beam (FIB). In many cases, however, this method does not provide adequate control of the tip's shape, most importantly its shank angle. Additionally, some multi-layer samples suffer from inhomogeneous milling rates along the various layers - especially when dealing with varying material hardnesses. There are other types of samples that do not lend themselves to annular milling, e.g. non-conductive materials that tend to charge when processed using ion beams.

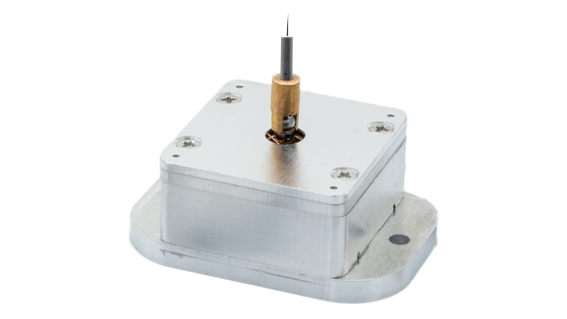

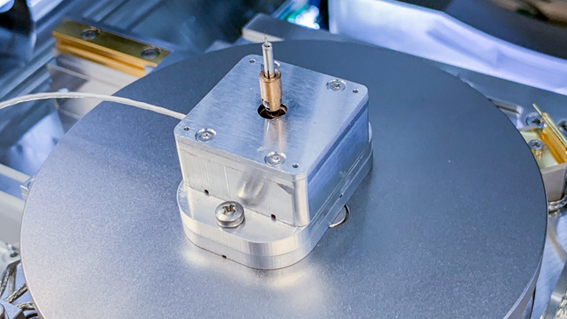

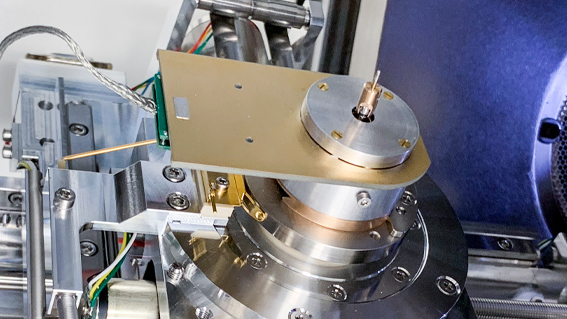

In these cases a 'lathe' inside the FIB/SEM is the solution. The Nanolathe is a two-axis positioning device comprised of a linear positioning method stacked on to a 360° continuous rotation drive. After centering the rotation axis under the beam using the microscopes's sample stage, the region of interest (ROI) can be positioned at the center of the Nanolathe's rotation, using the linear shifting mechanism. The Nanolathe's ultra-precise rotational drive provides a concentricity in the range of 100 nm.

Back to top

Back to top Site map

Site map